Pressure feed spray guns

Pressure feed spray guns explained what they are used for and benefits for using them.

This is a spray gun to which the paint is forced by pressure from a tank, fluid cup or pump this type was once often used, but still used in various forms in some environments.

The gun is fitted with an air cap and fluid tip combination that does not siphon the paint and the fluid tip is generally flush with the air cap. A pressure feed gun is used when large amounts of the same colour material are being sprayed, when the material is too heavy to be siphoned from a cup or container by suction, when extra fast application is required, or when large amounts of work need to be done very quickly, particularly on large or commercial vehicles.

In all cases where large amounts of the same material have to be applied, the use of a pressure feed tank is recommended.

- A very large amount of work that can be done before filling is necessary, thus obviating the waste of time that would be entailed in constantly filling the smaller container.

- The spray gun may be turned to any angle to coat the work effectively.

- The material is fed to the gun in greater volume than any other method, particularly if heavy paints are used.

- Less air pressure is required to obtain speed of operation.

- Waste of paint and losses by evaporation are eliminated.

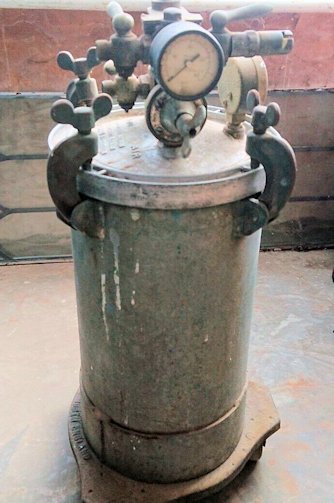

The principle of pressure feed is the application of low air pressure on the material in the tank so that it is forced through fluid hose to the spray

gun. Air pressure is controlled by an air regulator on the lid and a pressure gauge is provided. Pressure feed tanks are in many cases provided with a light insert container that greatly facilitates cleaning and change of material; some tanks can be mounted on a castor base, making removal from place to place an easy matter. The tanks are strongly constructed to avoid any risk of distortion under pressure and are usually galvanized inside and outside.

The lid is held on by clamps and is fitted with a gasket to prevent air leakage. There is a safety valve, an air release valve and at least one air and one fluid draw-off cock, but on the larger tanks there are two or three additional air and fluid cocks, so that the tank can be used by more than one operator. Provision is made for a hand-operated agitator to keep the material properly mixed and for large-capacity tanks it is advisable to have an agitator driven by a compressed air motor. The air motor ensures that the paint is kept at a constant consistency even during periods when the gun is not used.