MAN Nutzfahrzeuge AG history

Commercial vehicles in Munich , Germany

The Munich- based MAN Truck & Bus SE ( MAN Nutzfahrzeuge Group ) is the largest company of the German MAN Group and one of the leading international commercial vehicle manufacturers .

History

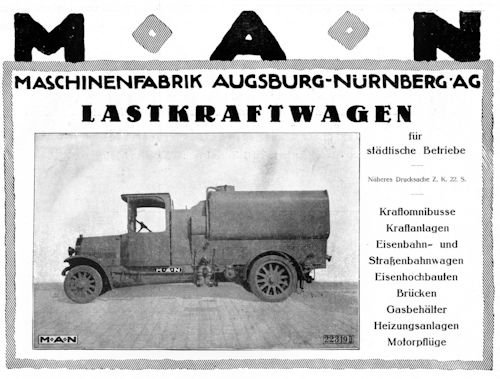

The roots of today's MAN Group lie on the one hand in the Ruhr area and on the other in southern Germany. The oldest forerunner company is the St. Antony ironworks, founded in 1758 in Oberhausen , which also marks the origin of the coal and steel industry in the Ruhr area. In 1808 it was merged with two neighboring ironworks to form the steelworks union Jacobi, Haniel & Huyssen.From 1873 Maschinenbau-Actiengesellschaft Nürnberg) to Maschinenfabrik Augsburg-Nürnberg AG and in 1908 finally to M. A. N.

In 1915, after lengthy negotiations with the Swiss entrepreneur Adolph Saurer , Anton von Rieppel succeeded in founding a joint venture company. The joint venture between Automobilwerke Adolph Saurer and the Maschinenfabrik Augsburg-Nürnberg AG was entered in the Nuremberg commercial register on June 21, 1915 as "Truck Works MAN-Saurer". The MAN Saurer GmbH first produced trucks in Lindau on Lake Constance, and as of November 1915, the relocation of production began to Nuremberg, which was completed 1916.

In 1921 MAN and the Haniel Group bundled their oil interests in equal shares in Oelhag . A portion of the shares was in the 1920s to the Atlantic Refining , the remaining shares during the Great Depression completely to the German-American Petroleum Company and Rhenania-Ossag .

Also in 1921, the Gutehoffnungshütte under Paul Reusch took over the majority of the then financially troubled MAN; until 1986 the group was now called GHH. Through targeted investments and purchases from processing companies - for example Deutsche Werft (1918), Ferrostaal (1921), Zahnräderfabrik Augsburg, vorm. Joh. Renk (Act. Ges.) (1923) and Deggendorfer Werft und Eisenbau (1924) - the company rose to become a nationwide group.

At the same time, however, GHH's economic situation deteriorated significantly. The reasons for this were, among other things, the reparation demands on the Weimar Republic after the First World War , the occupation of the Ruhr and the Great Depression . In just two years, the number of employees at MAN fell from 14,000 in 1929/30 to 7,400 in 1931/32. While civil business largely collapsed at that time, military business increased considerably with the armament under the Nazi regime . GHH / MAN companies supplied submarine diesel engines, tanks and cylinders for projectiles and all kinds of guns.

During the Second World War , the MAN plant in Augsburg, as a production facility for submarine diesel engines, was the target of air raids . The Nuremberg plant was also repeatedly hit , mainly because of the Panther battle tanks built there . At the same time, Otto Meyer advocated maintaining the production of civil commercial vehicles for as long as possible. In 1941/42 1085, 1942/43 1719 and in June 1944 even 63 civilian trucks were built before the Nuremberg halls and machines for truck construction were almost completely destroyed by air raids in October 1944.

At the GHH / MAN group, prisoners of war and concentration camp inmates had to do forced labor. In 1944 alone, around 31,500 forced laborers were employed in the group, of which around 8,500 were employed by MAN.

After the end of the Second World War, the GHH group was unbundled by the Allies . A vertical integration, to mining, iron and steel production and processing are in the group under a roof, was no longer allowed. The Gutehoffnungshütte together with the southern German MAN companies therefore concentrated on mechanical and plant engineering as well as the areas of commercial vehicles and printing machines; mining had to be abandoned. This was supported by strategic company acquisitions and sales. In addition to a joint venture concluded in 1953 with the Chinese Jinhua Youngman Vehicle Co. Ltd.the takeover of the truck and bus division of the commercial vehicle manufacturer Büssing (1971), the sale of the shares in Deutsche Werft (1966/67) as well as the takeover of the printing machine manufacturer Faber & Schleicher and the merger to form MAN Roland Druckmaschinen AG (1979).

At first, MAN only built medium and heavy trucks. When the need arose in the 1960s to offer even light vehicles, MAN was looking for cooperation with other manufacturers for cost reasons.

MAN-Saviem From 1967 MAN cooperated with the French commercial vehicle manufacturer Saviem , which belonged to Renault . Saviem was responsible within this cooperation for the light and medium vehicles (7.5-12 t), while MAN supplied the heavy vehicles (12-30 tons). Some of the light and medium-sized trucks were manufactured entirely by Saviem (and fitted with the MAN logo) and some were assembled by MAN at prefabricated parts. The permissible total weight was depending on the version between 4 t and 12.3 t, the diesel engines came from Saviem. The vehicles were offered until 1977 in Germany under the brand name MAN, but were not very common here. The pressing tools were made after completion of production to the Czech manufacturerAvia divested, who continued to make the cabin for years .

F8 Hauber 1951 was the first heavy truck after the Second World War, the type F8 on the market. It was designed as a classic hood car , the headlights were already integrated into the fenders and no longer free-standing. The F8 already had a direct injection - diesel enginewith remarkable 180 hp for this time. In 1953, the cab was redesigned, was wider and now offered more space. From 1953 appeared externally and constructively similar models under different type designations, which, however, at lower comparable payloads had lower engine performance, so that the F8 initially remained the "flagship" of the truck program. The production ran - at last only for the export - until 1963.

Pontoon-Kurzhauber In 1956, MAN introduced a new generation of hood trucks. The engine was no longer completely in front of the cab, but was a piece pushed into this. The vehicles could be built a little shorter than before. The design was based formally on the car construction: pontoon form instead of the former freestanding fenders and headlights.

The engine was made by diesel engines from our own production, the permissible gross weights were between 4.3 and 30 tons. The vehicles were available in numerous versions: ( flatbed , tractor , dump truck , etc.). Also a variants with all-wheel drive were availableIn 1969, the Kurzhauber were revised; most striking feature were the now in the bumper offset headlights. In these vehicles, the entire stem including the fenders could be folded upwards to improve the accessibility to the engine. Some types of vehicles were still produced in the old design until 1972, in Turkey , the first generation was even manufactured until 1977. The second generation production ended after 25 years of construction in 1994.

The MAN-Kurzhauber found a wide distribution as construction vehicles and in the fire department also abroad. Similar to the Daimler-Benz short-haulers , they were very sturdy and designed for easy maintenance and repair.

Great ground clearance and steep bank angles ensured excellent off-road capability. By standing in front of the front axle engine, the rear axle was relieved and thus offered a lot of payload, which predestined the Hauber as a tractor . Legislation on vehicle length ultimately meant the end for hood cars in Europe for economic reasons.

The "Pausbacke" While there was already a factory-mounted front- handle - Pendants to the medium-heavy models of the previously discussed Kurzhauber truck from 1957 , heavy cabs were often still equipped at this time on individual customer request with cabs independent coachbuilder. But here, too, MAN worked on its own model. After somewhat awkward-looking attempts, the manufacturer had found in 1960 the final form for the heavier models. This new design was used in models of the type 770 F and above.

Constructively, the new model family resembled the heavier hood car. To emphasize the family resemblance she received at the front corners - where the fenders ended the fenders - slight bulges, which earned the nicknamed "Pausbacke" the so-equipped vehicles. The model was particularly popular in long-haul long-haul cabs on the 10.212 F / FS (and other names) models. The "Pausbacke" was built until 1967.

F 7, F 8 and F 9 In 1967, new cabs with a completely new appearance were presented. The new cab originated from the French cooperation partner Saviem , with whom MAN had entered into a technical and sales partnership between 1967 and 1977.From 1972 accounted for on the front next to the radiator grille arranged additional grille with chrome trim (F7), the pontoon shrouds still remain. The ribs of the radiator grille now ran horizontally (F8). Furthermore, after taking over this manufacturer, the Büssing logo (the Braunschweiger Löwe ) has now been affixed to all trucks below the MAN logo and has remained MAN's trademark to this day. A light faceliftfrom September 1979. Recognizable on a new bumper, plastic coated, with larger headlights. Regardless of the engines installed. Since MAN produced its own underfloor engine starting in 1979, the production of the old Büssing engine was discontinued, the Büssing lettering now also dropped on the radiator grille and was replaced by the usual Diesel lettering. From 1981/1982 was the last major facelift of the F8 series. The most striking feature is the further down and enlarged turn signalsand a revised instrument / dashboard support. And just as conspicuously the Diesel lettering did not apply. In the medium-sized vehicles of the "new middle row" introduced from 1983, the radiator grille is lower than in the heavy version. D08 engines and custom chassis brought customized payloads to the range.

Heavy trucks of the TGS and TGX series, weight class 18 to 50 tonnes, are produced in Munich . An additional plant for the fast-growing markets outside Western Europe was opened in October 2007 in Krakow (PL). Light and medium trucks of the TGL and TGM series in the class 7.5 to 25 tonnes are manufactured in Steyr . Special vehicles such. Heavy goods vehicles up to 250 tons and special vehicles for off-road use as well as the major order from the British MoD are being built in Vienna .

"Premium" buses are manufactured at Plauen ; City buses in Starachowice (PL, Star Trucks ). Travel and intercity buses are produced in Ankara ( Turkey ).The MAN engines for the o. G. Trucks and buses are made in Nuremberg .Further locations are in Pinetown and Olifantsfontein ( South Africa ) and Querétaro ( Mexico ) .Joint ventures exist with Chinese companies Sinotruk in Jinan and Yutong in Zhengzhou . For sales and service of MAN vehicles in France and the Benelux countries has existed since 2007, a joint venture with the French trading company Pon , the MAN Region West BV is . Since September 4, 2009, MAN trucks are also produced at the UzAvtosanoat in Tashkent , Uzbekistan , in the new joint venture bearing the name MAN AUTO-Uzbekistan , In another joint venture with Rheinmetall , vehicles for military use will be manufactured at the sites in Kassel and Vienna . Approval was granted by the Federal Cartel Office in March 2010 ( Rheinmetall MAN Military Vehicles GmbH ).

The vehicles are usually delivered as completely disassembled kits . In addition, Weichai Power MAN engines are built under license .As a special feature of previous company acquisitions in Austria, until 2008 it was possible to acquire MAN vehicles with a special radiator grille from Steyr or ÖAF .

MAN Büssing

After the takeover of the competitor Büssing in 1971, MAN picked up some truck and bus models from Büssing in his own program and offered them after continuation of the previous name until the end of January 1, 1972 under the double name "MAN Büssing" , However, these vehicles have already been registered as MAN production at the Federal Motor Transport Authority . While the still quite modern Büssing buses and trucks with underfloor engine(with horizontal cylinders) remained almost unchanged in the program, the production of the front handlebar truck with conventional stationary engine and the hood car was discontinued in that year. After 1973, the former Büssing cab was initially replaced by that of the comparable MAN-owned models, while the technical underfloor construction of Büssing remained in the program for the time being and was continued by MAN for several years. After a transitional period disappeared in 1979, the name "Büssing" of the vehicles of "MAN", where then instead of the double name "MAN Büssing" only the name "MAN" was. However, the Braunschweig Löwe of the Büssing company logo is still part of the MAN logo and the radiator grille in a modernized form to find MAN commercial vehicles.

Military vehicles

Between 1956 and 1975 there was a more edgy version of the pontoon short-haul under the model names 630 L2A and 630 L2AE for the special needs of the military . This four-wheel-drive vehicle, which was even more robust than the civilian Ponton-Kurzhauber constructed vehicle after the suspension in the military often by the police, fire departments , the Technical Relief Agency ( THW ) and other aid organizations continue to use.

The all-terrain MAN gl had been designed as a military vehicle for the Bundeswehr . Since the German Federal Armed Forces existed as clients on air-cooled engines, these were supplied by Deutz - MAN produced only water-cooled diesel engines . However, vehicles with MAN engines were also built for export; in some cases the vehicles (also with other cabs) were used by fire brigades as airfield fire fighting vehicles. The production began in 1976.

MAN has been one of the main suppliers of military vehicles since the formation of the Bundeswehr. The KAT-1 generation is now obsolete and will be replaced. In this case, vehicles for the non-tactical area z. T. replaced by TGA models (see above). In addition, the Military Division of MAN supplies more than 150 other armed forces on all continents.

In 2005, MAN won the United Kingdom Department of Defense tender for procuring over 7,200 support vehicles . This makes MAN one of the largest equipment suppliers worldwide. These special vehicles will be built in the former ÖAF plant in Vienna-Liesing .

Taking into account the changing threat picture, MAN, in cooperation with Krauss-Maffei Wegmann (KMW), has developed an armored version of the SX 32.440 8 × 8 , which has already been successfully tested by the Bundeswehr as part of the KFOR mission in Kosovo and is now ready for series production Has. The vehicle will be delivered in large numbers to several European armies and, in addition to a cabin that is protected in Level III ( STANAG ), also has a remote-controlled weapon station and a hook loading system, Thus, the vehicle is adapted to current threat scenarios and logistical concepts. Since March 2010, the model series has been produced as part of the newly founded joint venture Rheinmetall MAN Military Vehicles GmbH.

Buses

In 1915, MAN began to build buses with Saurer buses . In the beginning, a distinction was made in the equipment mainly between buses and coaches . Since the 1950s, a distinction was then made between city buses and intercity buses . The intercity buses have more seats than a city bus and in front usually only a single-width door.

MAN manufactures buses for regular service as well as coaches . In 2001, the company Gottlob Auwärter GmbH & Co. KG took over the bus division Neoplan . This merger for the production and sale of buses was known as NEOMAN until January 2008 . As of February 1, 2008, NEOMAN was fully integrated into MAN Nutzfahrzeuge AG , while the "Neoplan" brand continues to be used.

In the late 1960s the standardization came as a result of scheduled buses, the first after German VÖV constructed guidelines standard buses on the market, most recently those of MAN. These were in the 1970s with the type designations SL for S tandard L inienbus, SG for S tandard G elenkbus , SÜ for S tandard Ü berlandbus and SD for S tandard D in oppeldeckerbus.

At the beginning of the 1980s, MAN introduced a 23-meter long MAN SGG 280 double-articulated bus capable of accommodating 225 passengers. The only copy ran u. a. for a short time at Lembke, Koschik u. Co. in Celle as a trial in the regular service.

From the mid-1980s, the first generation of the standard buses was replaced by the 2nd generation of the VÖV developed by the FFG . At MAN, the first and second generation were built in parallel for some time. The bus SÜ 240 was built the longest, of which some were delivered to the Deutsche Bundesbahn in 1990 .

MAN was the second-largest manufacturer of VÖV standard buses after Daimler-Benz. Since the design of the VÖV buses was a standardization project, the standard buses from MAN were visually very similar to those of the competition, in particular Mercedes-Benz ( O 305 ), Magirus-Deutz and Büssing . The Hungarian bus manufacturer Ikarus also produced buses in accordance with the VÖV guidelines ( Ikarus 190 ) in the 1970s and delivered them to the Federal Republic of Germany ( Verkehrsbetriebe Hamburg Holstein ). These buses were not under license, but contributed to by a license Rába- produced by MAN in HungaryDiesel engine .