Ё-mobil

Russia from 2014

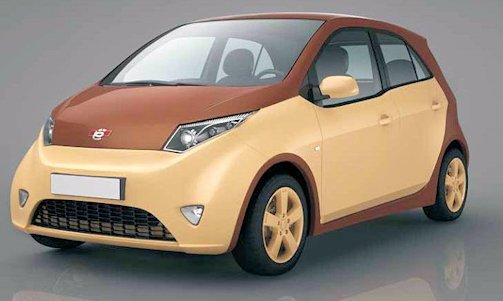

The ё-mobil was a Russian hybrid electric vehicle. In this pure serial hybrid, the drive power comes from a generator to the electric motors, which is driven by a continuously running (gas, gasoline or diesel) rotary piston engine. A capacitor is used for buffering. Series production of this vehicle was scheduled for the second half of 2014. The ё-mobile corresponds to the size ratios of the Toyota Yaris, the Hyundai Getz and the Ford Ka.

History

The development of a city car with hybrid drive was initiated by the Russian-Belarusian holding company "Yarovit Motors" and later presented to the businessman and billionaire Mikhail Prokhorov. A collaboration between "Yarovit Motors" and Mikhail Prokhorov began earlier, in 2004 special latches of "Yarovit" were used by Norilsk Nickel, which he was a partner.

At the first presentation on April 12, 2010, the Russian investor group Onexim and "Yarovit Motors" announced the start of the project for the city car with hybrid drive. The new company "Gorodskoj Avtomobil" was founded, with 51% holding ONEXIM and 49% Yarovit Motors shares. The development budget until the start of series production amounted to 150 million euros.

On October 12, the new car was introduced. Two models were shown that have four seats and are based on the same platform. The first model is a hatchback for the family, the second model, a cross-coupe, is aimed at young people.

The design of ex and interior comes from designer Andrej Trofimchuk. Belarussian designer Vladimir Cesler proposed the two-tone paint scheme, based on a previous project of the company "Russkij Awtomobilnyj Disajn" (translated: Russian automotive design). The colour ivory should remain unchanged, while the second colour is variable. The design should establish itself as a stylistic sign of the manufacturer and at the same time symbolize the hybrid concept.

The name for the car was chosen and published on numerous proposals in a competition "So I call the city car" on November 9, 2010, as well as the brand logo, which comes as the name of Cesler.

As planned, on December 13, 2010, three working prototypes of the hybrid car were presented - ё-minivan, ё-transporter and ё-cross-coupé. For presentation purposes, the bodies were mounted on simple steel frames and used two-cylinder four-stroke engines of the MPE750 type from the German manufacturer Weber to the drive.

On 15 February 2011, the construction of a first plant near the town of Marjino in the Leningrad Oblast was announced. The capacity of the plant should be 10,000-20,000 cars a year, with the ability to increase capacity later to 40,000-50,000. In the future, five more plants are to be created throughout Russia. In addition, the construction of a single-component manufacturing facility is planned to provide up to 100,000 cars a year with spare parts.

On February 21, 2011, an optimized version of the "ё Cross Coupé" was presented, which took into account the wishes of the visitors of ё-mobile exhibitions. The main focus of the bodywork changes is on the comfort: it kept the wheelbase of the car, but made a five-seater with five doors out of it, although it remains with the term "Coupé". Thanks to the shortened bonnet, the front seats have been moved forwards and the rear seats, thanks to the higher roof, have moved to the rear. Thus, more seating space was created. The space in the trunk was increased to 450 l (formerly 400 l); when the rear seat is folded, it increases to 1100 l. The slight change in bodywork has little effect on the dimensions: Length: 4100 mm (old: 4065 mm), height: 1550 mm (old: 1495 mm), ground clearance: 210 mm (old: 200 mm).

The car was to be built in the three body versions. Petrol, gas (methane or a mixture of propane and butane) should be used as fuel. The main energy source is a permanently running rotary piston engine, which drives the electric generator. The energy produced is stored in a supercapacitor and directed to the two electric motors - one per axle - which drive the wheels by means of differential gear, which is a permanent four-wheel drive and thus ensures good traction even in poor road or weather conditions. All electrical units are controlled by a specially designed computer system, which ensures few cable connections. The dashboard is equipped with an electronic display and a touch screen.

Special features of the ë-mobile

- The number of parts and aggregates should be radically reduced (2 to 2.5 times less than in a current contemporary car)

- Modular construction consisting of 400 interchangeable modules, which allows uncomplicated production, service and repair of the car. Furthermore, this will make it easier to adapt to future innovative developments and to the individual needs of the owner.

- At the beginning of the development, a body made of aluminium frame in combination with body parts made of basalt fibres was planned, but later decided in favour of a supporting structure made of polypropylene-based composite material. The developers speak above all of far better strength properties and cold resistance than it is the case with metals; while the production cost should be much lower, which is associated with the peculiarities of the manufacturing process from the gas raw materials. In November 2010, the implementation of a crash test was planned by one of the European agencies. The work on bodywork is done by the company Magna carried out, so the project developers. It is further stated that the body will meet all European requirements regarding passive safety of the occupants. This is to be achieved mainly by the honeycomb design of the parts and by the support structure of the bodywork, which will ensure that the energy is absorbed and dampened in an impact of the entire body. The repairability of such a solution is not highly appreciated (after serious damage it might be necessary to replace the entire bodywork), although this circumstance is fully in line with the concept of building and repairing a modular vehicle. The individual modules are made to order by the manufacturer and installed by the service centres.

- Energy storage uses one unit of the 100 kg supercapacitors, which fits under the rear seat. The full recharge of the unit should take about ten minutes.

- The electronic locking of the top speed at 130 km / h explain the developers with the desire to minimize the number of fatal accidents on the road. In addition, they expect that this limit will soon be regulated by law in many places.

- Service intervals: 40,000 km

- Engine life: 1 million km

- Price: 350,000 to 450,000 rubles (about 9,000-11,500 €)

- The production of the vehicles should take place in the domestic mini-plants with the annual capacity of 10000 cars.

- The aim of the Euro 5 standard is to ensure that the combustion of fuel in the toroidal chamber of the engine, where the pistons are located, is not accompanied by oil flow. The burning happens so "dry". The concept of the presented rotary piston engine provides a possibility of "smooth" turning, in which the precision oil-cooled precision pistons interact with the surface of the combustion chamber by means of temperature-resistant rings made of fluoropolymer.

Equipment

For all models - as of December 2010 - the following equipment was provided:

- Body made of polypropylene - composite

- Propulsion: a rotary piston engine with an output of 45 kW / 60 hp coupled to an electric generator (in Moscow, vehicles of this power are exempt from tax). Gasoline can be used as fuel together with compressed or liquid natural gas or just one of the fuel types. For the version with compressed natural gas, compliance with the Euro 5 standard is specified.

- electric drive with permanent four-wheel drive or front-wheel drive *; In each case, a brushless DC motor with 15 kW / 20.5 hp power is installed per drive axle. The drive also includes a system for energy recovery during braking, with the help of the supercapacitor.

- Range with one tank of internal combustion engine up to 1100 km, up to 2 km only with energy from the condenser

- Tank capacity: 20 l (petrol) and 14 m³ compressed natural gas or 20 l LPG

- ABS and ESP

- Driver and passenger airbag

- Cruise control

- air conditioning

- Main lighting with LED daytime running lights

- Touch screen, possibility of colour and design selection of the instrument display

- Multifunctional steering wheel

- Navigation system GLONASS and GPS with the possibility of using the free maps OpenStreetMap. It is also possible to edit and download map data via the Internet or USB.

- Start-stop system

- Light-alloy or steel * wheels with run-flat tires, so that the car can drive up to 80 km / h even after a puncture. Therefore, a spare tire is not provided.

- Suspension: front MacPherson suspension, rear torsion bar suspension

- multimedia system consisting of:

- Internet connection (4G from "Yota", other providers possible)

- Media player with a USB port

- Mobile phone with Bluetooth connection

Technical

-

Technical details and specifications

ë minivan

ë-Cross-coupé three-door

Dimensions, in mm

3892 × 1815 × 1611

4065 × 1832 × 1495

Seats including driver

5

2 + 2

Number of doors

5

3

Number of airbags

2

2

Empty weight kg

700

650

Max. Total weight, kg

1200

900

Load capacity, kg

-

-

Load volume, l

-

-

drive

Four-wheel / front *

Four-wheel / front *

Rim size, inch

R16 (R15 *)

R17 (R16 *)

Ground clearance, mm

170

200

Maximum speed (electronically controlled), in km / h

130

130

0 - 100 km / h, sec.

"Eco -" - mode

11

10

"Sport" mode

8th

7

"Ice" mode

14

14

Fuel consumption, l / 100 km

3.5

3.5

ë-Cross-coupé five-door

ë transporter

Dimensions, in mm

4100 × 1832 × 1550

4200 × 1880 × 1870

Seats including driver

5

2

Number of doors

5

3

Number of airbags

2

2

Empty weight kg

650

650

Max. Total weight, kg

900

1550

Load capacity, kg

-

750

Load volume, l

-

4000

drive

Four-wheel / front *

Four-wheel / front *

Rim size, inch

R17 (R16 *)

R16 (R15 *)

Ground clearance, mm

210

170

Maximum speed (electronically controlled), in km / h

130

130

0 - 100 km / h, sec.

"Eco -" - mode

10

14

"Sport" mode

7

-

"Ice" mode

14

18

Fuel consumption, l / 100 km

3.5

4.0