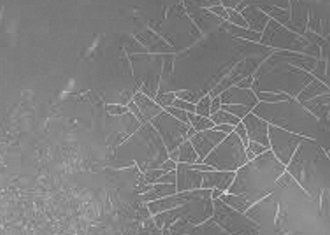

Paint Cracking and shrinking Problems

This section includes shrinking and splitting (of undercoats). To repair Flat out cracked area, or wash off with proper thinner or solvent, and repaint.

Cause

1. Material not thoroughly stirred before use. If some of the undercoat has been previously used without stirring thoroughly, it may have upset the pigment to binder ratio to such an extent that the remaining material will always give trouble.

2. Surface not completely clean.

3. Insufficient flatting and feather-edging.

4. Oil or water in airline.

5. Insufficient thinning of undercoat.

6. Use of wrong or poor thinner.

7. Undercoat applied too heavily, especially first coat.

8. Blowing of air on wet film in attempt to speed up flash-off and drying.

9. Applying undercoat on a too hot or too cold surface.

10. Insufficient drying time allowed for between coats.

11. Use of too coarse a grade of wet and dry.

Prevention

1. Stir undercoat thoroughly each time before use.

2. Use wax and grease remover to clean surface before and after.

3. Flat well with the recommended grit paper. Feather-edge well back into old finish.

4. Keep airlines free of water and oil.

5. Thin undercoat fully with the proper good-quality thinner.

6. Apply undercoat in medium-thin coats, especially the first coat.

7. Avoid blowing air on wet undercoat.

8. Allow room, metal, and material to come to equal temperatures, preferably between 16 and 24 °c.

9. Allow each coat to dry thoroughly before applying succeeding coat.