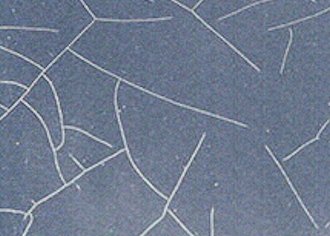

Paint Crazing Problems

This section includes alligatoring, crow-footing and hair-lining (of colour coats).

To RepairThoroughly remove entire crazed finish and repaint. Good-quality modern finishes properly applied rarely, if ever, fail by crazing. The film defects, all related, and named to describe their appearance, are generally the result of the following:

Cause

1 .Application of new finish over an old finish which has already crazed.The crazing in the old finish may not have been visible without close inspection using a magnifying glass.

2 .Use of poor-quality, too brittle finishes.

3 .Application of new finish over an old finish of new undercoat which is too soft.

4 .Application of new finish over undercoats which are too thick or not thoroughly dried.

5 .Application of excessively thick finish coats.

6 .Mixing of unproven additives, such as gloss improvers, with the colour coat.

7 .Insufficient stirring of materials to incorporate all the pigments.

8 .Use of shellac sealers.

9 .Use of poor quality or improper thinner.

Prevention

1 .Always use highest-quality materials; they are much cheaper in the long run.

2 .Inspect the old finish carefully with a magnifier. If old finish shows any signs of crazing, remove completely before re-finishing.

3 .Apply undercoats in medium-thin coats, allowing plenty of drying time for each coat.

4 .Do not use too much material.

5 .If the job has previously been repainted, flat down thoroughly to reduce total film thick-ness.

6 .Do not add anything to refinishing materials not specifically recommended by the manufacturer; then follow directions carefully.

7 .Stir all materials thoroughly each time before use. Thinned materials settle more rapidly, so be sure to agitate material in spray cup occasionally during use.

8 .Always use good and correct thinner, as well as a sufficient amount.