How the sparks are produced needed in the engine

Here we look at How and why a spark are produced in the engine and whats parts make up the processes, in a traditional petrol engine.

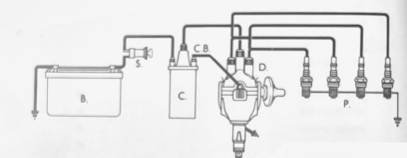

The ignition system produces the sparks necessary to burn the petrol-air mixture in the engine combustion chambers. It consists of a switch, battery, coil, distributor and spark-plugs.It is essential when tracing a fault in the ignition system to know how the system works, because each component has to be checked in turn.

The battery produces low-tension current (usually 12 volts) which, when the ignition is switched on, flows to the coil. The coil boosts this low-tension current, transforming

it into high-tension current (up to 30,000 volts).

Its primary winding is connected between the battery and the contact-breaker points in the distributor. As current flows through the primary winding, which is wrapped round a soft iron core, a magnetic field is created. This regularly collapses as the low-tension circuit is switched on and off by the opening and closing of the contact-breaker (CB) points. This collapse generates the high tension current in the secondary winding in the coil, which is connected by a high-tension lead to the distributor cap. Once this high voltage is produced, the distributor sends it to each spark-plug in turn to produce a spark at the correct time in each piston's four-stroke cycle. The spark-plug has two electrodes live and earth with a gap (usually •025 in.) between them, and the spark is produced when the high-tension current jumps the gap.

Battery and ignition switch

A fully charged battery puts out only 6 or 12 volts when the ignition is switched on. This low-tension (LT) current flows to the coil, where it is boosted to high-tension (HT) current of about 16,000 volts, but sometimes up to 30,000 volts. HT current is needed to provide the sparks that will fire the mixture in the combustion chambers and so turn the engine.

Coil

To do its job of transforming low-tension into high-tension current, the coil depends upon the contact-breaker. When the points open, LT current ceases to flow in the coil's primary winding (darker coils) and HT current is induced in the secondary winding (lighter coils). These flow to the distributor. The points close again, and the process is repeated.

Low-tension circuit

law-tension current flows into the coil's primary winding at a terminal usually marked SW (or +) for switch'. Another terminal, marked CB (or —) leads to the contact-breaker assembly in the distributor. When the LT circuit is broken, the magnetic field created by it collapses inducing high-tension current in a secondary winding in the coil.

High-tension circuit

The high-tension current flows to the centre terminal in the distributor cap, where it is passed to the rotor arm. Cables from the cap then carry HT pulses to each spark-plug in turn. Because of the high voltage, the HT leads are thick and heavily insulated. Modern leads have carbon centres and act as radio and television interference suppressors. Centrifugal advance as engine speed increases and pistons move faster, the petrol- air mixture must be ignited earlier, so timing of the spark has to be advanced. This is done through two weights linked to the distributor shaft. At increased speed they are thrown outwards and pull the cam, attached to them, round the shaft to open the points earlier and provide advanced ignition.

CB points and rotor arm

The rotor arm transmits HT current to electrodes lining the inside of the distributor cap as it turns on the distributor shaft. The HT pulses are passed on to each spark-plug in turn. The contact-breaker points beneath the rotor arm are opened by one of the high points on the distributor shaft cam, and closed again by a spring blade on the moving contact point.

Distributor and plugs

The contact-breaker points in the distributor control the timing of the spark. Its size is controlled by the gap between the electrodes at the tip of each plug. This is small (usually about •025 in.), but the high voltage of the current from the distributor cap, ranging from 16,000 to 30,000 volts, enables it to jump the gap, and produce

the necessary spark. Vacuum advance On distributors such as the Lucas, Suction in the manifold acts on a diaphragm that pulls the contact-breaker assembly forward so that the cam opens the CB points even earlier. When the throttle is wide open, suction is low and the CB assembly returns to normal. If it did not, the spark would occur too soon and perhaps cause over advanced ignition.