How a mechanical fuel pump works

The fuel pump is used to provide the pressure necessary to drive the fuel from the storage tank to the carburettor. There are two basic types of fuel pump, commonly used today, mechanical and electrical. The difference between the two types lies in the method of operating the pull rod.

The main difference between the mechanical and electrical pump is that in the latter case the pull rod is operated by a solenoid instead of a cam. The solenoid contacts are normally closed until the circuit is completed by the closure of the ignition switch. This energises the magnet coil and the armature is attracted to the iron core. The armature is attached to the diaphragm, which flexes, drawing in petrol through the inlet non-return valve. When the armature has almost completed its travel, the contacts are opened by action of the pull rod. This de-energises the magnet and allows the spring to return the armature and diaphragm to their original positions. The movement of the diaphragm forces petrol through the outlet non-return valve to the carburettor. The action then repeats at a rate determined by engine demand and will continue for as long as the ignition switch remains closed.

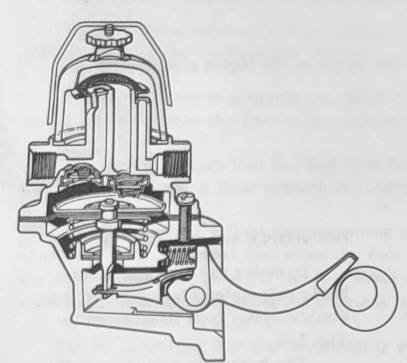

A mechanical pump actions is as follows:

(1) With no fuel being demanded by the engine, the flexible diaphragm is held by the spring, in the position shown in the diagram.

(2) When the engine is started, the pull rod is drawn down by a rocker arm operated from an engine driven cam, this causes the diaphragm to flex downwards. The volume of the chamber above the diaphragm is increased, reducing the pressure in the chamber. A spring is incorporated in the rocker assembly to prevent rattles when the pump is not delivering.

(3) Atmospheric pressure in the tank forces fuel past the inlet non-return valve into the pump chamber, the delivery valve being held closed

(4) The pull rod is released at the end of the stroke and spring pressure returns the diaphragm to its original position.

(5) The resultant increase in pressure forces the fuel through the delivery non-return valve into the carburettor, until the pressure is insufficient to operate the valve.

(6) The pull rod commences its downward stroke and the cycle repeats.