Zenith VN Carburetters

The Zenith Series VN carburetter overview and guide.

Features:

The Series VN carburetters are all downdraught types, having the following main body assembly features:

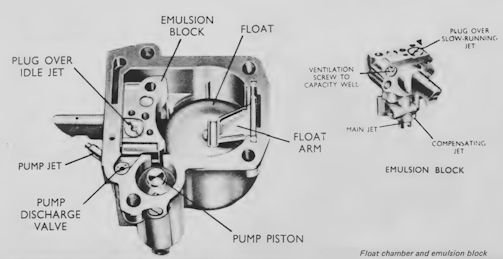

Main Barrel Assembly with Integral Floatchamber Cover.Floatchamber,Emulsion Block.

The unit sizes are based on 30, 32, 33, 34, 36, 37 and 42 mm diameter choke tubes. The basic design incorporates a depression operated economy device and a mechanically operated accelerating pump. There are however significant variations from the basic form and these are indicated by the change in type letter identification:

TYPE

- VNN Initial model

- VNN Economy Device and Accelerating Pump omitted

- VNR Speed Governor fitted

- VNT Thermostat Unit for Air Strangler Control

- VNP Economy Device omitted

Minor variations occur in some of the jet circuits. In the 42VN unit, the main and

compensating jet outputs are supplemented at high speed with additional fuel from Auxilliary Jet 29, or from a calibrated hole drilled in the emulsion block, over the main jet channel. Auxiliary Jet 29 is sometimes used in 32VN models. In some models the floatchamber is vented to the Air

Inlet Passage 12 but others vent to atmosphere directly.

Operation, Adjustment, Trouble Shooting:

Petrol Level:

The petrol level is determined by the float position when holding the needle valve closed against a fuel pump delivery pressure of 2.5 p.s.i. The float arm (or thickness of the needle seating joint washer) are factory set to give the following levels measured from the floatchamber top face.

FLOAT TYPE

Assembled unit METAL 18 mm 23/32 in

Floatchamber removed with float METAL 22.5 mm 7/8 in NYLON 26 mm 1 1/32 in

Float removed METAL 33 mm 1 5/16 in

Accelerating Pump:

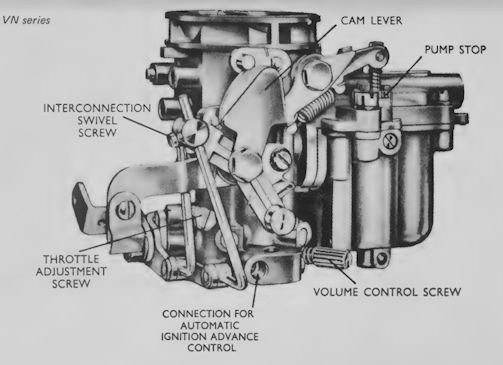

The accelerating pump is of the typical mechanically operated plunger type, with a stroke limiting Pump Stop that enables a short or long stroke to be selected for summer or winter use respectively.

The pump stop fits loosely on the pump rod and is held in place on the floatchamber cover by a spring. A long, or a short projection on the stop may be positioned to limit the travel of the pump operating lever, by lifting the stop against the spring and rotating it a half turn to. select the appropriate position. (Long projection - short pump stroke; short projection - long stroke).

The pump is operated by a two-part lever arrangement connected by a tension spring. The spring gives a follow-up movement to the pump piston, so extending the period of accelerating fuel injection when the throttle is opened suddenly; also, it facilitates change-over of the pump stop.